Solutions Smart Sorting

Smart

Sorting

for Increased Efficiency in the Industry

Successful companies have two central concerns: They want to offer their customers products of the highest quality while working efficiently and economically. An important step in production or processing is the sorting of materials, for example, based on their quality or chemical properties. However, that`s where traditional color cameras reach their limits. Smart sorting with EVK hyperspectral cameras offers industrial companies decisive competitive advantages.

The Challenge: Industrial Material Separation is Error-prone and Costly

Many companies still rely on separating materials on the assembly line by hand to differentiate materials, segregate high-quality components from low-quality ones, or to remove impurities to improve product quality. However, this manual sorting process is time-consuming, error-prone, and very expensive. Some processes already integrate color cameras, but they only provide limited information about the material flow. Color cameras only evaluate objects based on their color and cannot provide information about the chemical structure of the material.

The Solution: Sensor-based Sorting with EVK Hyperspectral Cameras and Inductive Metal Sensors

EVK offers customized solutions for optical systems and sensor-based image processing for manufacturing companies in various industries. The EVK HELIOS hyperspectral camera makes it possible to classify and sort materials based on their spectral signatures according to individual specifications. Unlike conventional cameras that only operate in the visible spectrum, a hyperspectral camera captures hundreds of spectral bands. Each point in the captured image has a spectral signal that provides insights into the chemical composition and the specific properties of the object. This makes it possible to classify materials based on their chemical characteristics, such as protein content, moisture, fat, sugar, salt, or starch content.

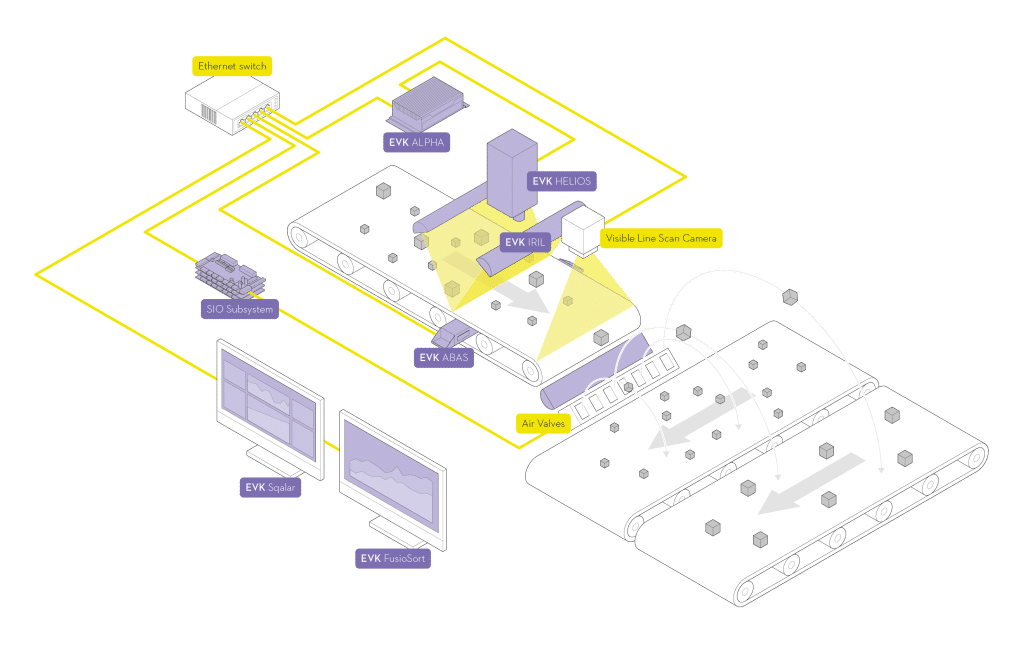

Thanks to the data processing platform EVK ALPHA and the specially developed algorithms, EVK HELIOS hyperspectral systems are able to reliably detect foreign bodies and extract valuable key data for precise and automated sorting commands. This real-time capability and robust design make the systems suitable for continuous 24/7 operation in industrial environments.

Furthermore, the EVK ABAS smart metal sensors provide spatially resolved information about conductive material in the product stream, can reliably detect ferrous and non-ferrous metal parts and communicate sorting commands.

Together with the EVK SQALAR analysis software, it is possible to collect data and create chemometric models easily and efficiently. The optimized and user-friendly application allows for flexible and rapid development of applications, minimizing development time and making the process cost effective.

If this technology is used, for example, in sorting processes, reaction times of less than 2 ms can be achieved with the algorithms. It is possible to remove non-recyclables immediately.

Competitive Advantages

for Our Customers

By choosing sensor-based, smart sorting with EVK products, you gain a competitive advantage over your competition and increase the efficiency of internal processes. This technology is used in various industries such as recycling, food, mining, or pharmaceutical industries to effectively classify materials for smart sorting decisions.

All Benefits at a Glance

Increased Productivity and Efficiency

Sensor-based sorting is faster, more efficient, and more accurate than sorting by hand. It increases productivity within the workflow and maximizes the output. Automating material separation saves time and manpower.

High-Quality Results

EVK's smart sorting solutions ensure that your products and materials always meet the highest quality standards. Quality features that are not visible to the eye or even color cameras can be detected by our solutions.

Fast Time-to-Market with Integrated EVK Solutions

Receive hardware, software, and integration services from a single source, reducing your development time.

Sensor Fusion

Combining hyperspectral cameras with metal sensors, color cameras, or other sensors maximizes results in many industrial applications.

Quantitative Analysis

Another advantage of EVK hyperspectral cameras is the ability to quantitatively analyze materials. This gives our customers the tools to sort materials based on analytical results and provides perfect basis for precisely monitoring and controlling production processes. In practice, this advantage is evident, for example, in determining the fat, sugar, or starch content as well as their distribution in food, or identifying the moisture content in wood, or determining the calorific value of SRF and RDF.

Overall, EVK hyperspectral cameras for smart sorting are an innovative solution efficiently segregate materials based on quantitative or qualitative criteria in various industries. We are proud to help our customers increase their productivity, improve efficiency, and gain a decisive competitive advantage.

How Does Smart Sorting with Hyperspectral Cameras Work?

Sensor-based sorting is complex but effective. Hyperspectral cameras capture and analyze the electromagnetic spectrum across a wide range of wavelengths. Unlike conventional cameras that can only capture visible light, hyperspectral cameras can capture a much broader spectrum. As a result, hyperspectral cameras are able to capture the spectral signatures of materials and identify them based on a database of reference values. The hyperspectral camera technology enables non-invasive and non-destructive data acquisition. This means that investigations can be carried out without affecting or altering the object or scene. The materials are then classified and automatically ejected, for example by air nozzles or valves, ensuring that only materials with the desired properties enter the production process.

More Info at

our Technology Center

Customization to Your Requirements

We can tailor our technology to meet the specific requirements of our customers and generate a customized solution. It is also possible to integrate the system in non-traditional settings and therefore in non-conventional sensor-based machines, e.g. in robots.

Sensor-based Sorting

Products for Smart Sorting

EVK offers various products for your sorting tasks, equipped with the latest technologies and customizable to your specific application needs. Discover our portfolio to optimize your daily workflows.

Hyperspectral Imaging

in the Sorting Process

EVK HELIOS hyperspectral cameras are available as flexible core cameras or with integrated classification systems. The cameras identify the chemical properties of different objects and materials and allows for non-contact and non-destructive analysis directly in the line. They operate with spatial resolution and in real-time.

Inductive Sensors

in the Sorting Process

The spatially resolved, inductive metal sensor is mounted under a conveyor belt and is used to detect ferrous and non-ferrous metals in the material stream.

Analyzing

in the Sorting Process

The EVK SQALAR software analyzes the chemical properties of individual objects qualitatively and quantitatively and helps to develop chemometric models for industrial applications. EVK STREAM Supervisor monitors industrial material flows at multiple points and the key data obtained provides information about material distribution, belt occupancy, and material composition.

Real-Time Image Processing

in the Sorting Process

EVK ALPHA, an image processing platform for spectral data, combined with the EVK HELIOS EC is a powerful duo for in-line inspecting and monitoring in real-time.

Professional Service

in the Sorting Process

Our EVK professional service team puts their extensive knowledge at your disposal right from the development phase and supports you throughout your project during conception, integration and commercialization.

Industrial Data Analytics

System Integration

Professional support for Sorting solutions

Feasibility Studies

Commissioning

Product Training

Maintenance and Service

Application Development

EVK product accessories to integrate our sensor-based solutions

- Hyperspectral Camera Lenses

The selection of the right lens depends on various factors such as the distance to the conveyor belt, the incident light, material size, or the required resolution. Our team supports you in choosing the right lens for your specific sorting application. - EVK IRIL

EVK IRIL is a lighting unit specifically designed for EVK HELIOS hyperspectral cameras, providing a perfectly balanced light intensity for optimal image quality. - SIO Subsystem

To perform sorting tasks, the 48k SIO subsystem controls the valve. - EVK FusioSort

The EVK FusioSort software sets sorting-relevant parameters such as shot time or material weight. - EVK Libraries

To integrate our products into existing systems, we offer various software libraries.

Sensor-Based Solutions in

Your Industry

Sensor-based sorting is successfully applied in various industries. In the food industry, for example, EVK systems are used to detect foreign bodies such as stones, glass fragments, or metal parts and communicate sorting commands in real time. In the recycling industry, waste can be sorted based on its chemical composition for environmentally friendly and legally compliant recycling.