Attributes such as safety, quality and speed are strong differentiators for domestic companies when competing globally. Everyone is talking about digitalisation, Industry 4.0, environmental protection, and 5G. Modern manufacturing facilities around the world are therefore striving to implement reliable quality control for their incoming and outgoing goods. To remain competitive with their products on the international market, optimising production is becoming increasingly important for various sectors such as food, recycling, timber as well as other industries connected to the production of consumer and capital goods.

Italy, with exports of goods and services totalling 31.8%¹ of GDP, is one of the top five exporting countries² both within the EU and globally. Of its total export volume, Italy exports 12.6 % to Germany, 10.5 % to France and 9.2 % to the US. At the same time, it imports 29.3 % of its GDP. This means that in the future, Italian business will have to pay even more attention to the quality of the goods it imports to ensure Italian consumers‘ safety and to continue delivering the best Italian quality abroad when exporting.

Modern quality assurance methods often inadequate

Many quality control methods in the food, chemical and pharmaceutical industries, as well as in the production of solid recovered fuels (SRF)/refuse-derived fuels (RDF) and secondary raw materials in the recycling industry, are based on laboratory results obtained using high-precision measuring instruments and methods. The small number of random samples used means that these methods cannot provide qualified information on the entire product flow. Consequently, this approach does not meet today’s quality and safety standards in any way.

Let us take an example from the food industry. In poultry processing, the wooden breast defect occurs. Nowadays, employees in the quality control department of chicken meat processing companies have to detect whether this defect is present by touching the meat with their hands. New sensor technologies connected to the facility’s control system – such as hyperspectral imaging – detect whether the chicken meat is suitable for consumption in a fraction of a second on the conveyor belt and therefore determine the product‘s further processing. As opposed to manual quality control, it is possible to guarantee far higher quality and safety standards for consumers. In addition, the company saves time and money by reusing the product.

What is hyperspectral imaging?

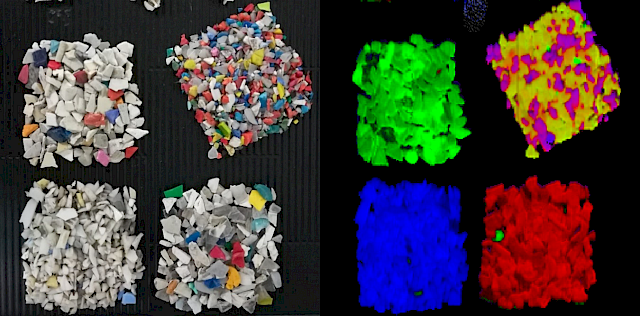

Hyperspectral imaging technology, which is at the heart of this new quality control system, comes from astronautics and is also used to explore distant galaxies. It does not recognise actual colours, but identifies the chemical structure of the material by observing the reflected light and its wavelength. It is therefore possible to measure the chemical composition of a particular material, as shown in the two images below:

On the left you can see an original photo of various plastic flakes as they are used for energy recovery in different incineration facilities. On the right-hand side you have the same plastic flakes, which were observed with hyperspectral imaging, then divided into different categories and classes and converted into a 24-bit RGB false colour image visible to the human eye. In this process, regardless of their real colour, we assign the different types of plastic a colour specified by us to clearly distinguish them from each other. We determine the type and quality of the material. In the picture above we can see the different types of plastic in different colours: ABS (acrylonitrile butadiene styrene) in red, POM (polyoxymethylene) in blue, PC (polycarbonate) in green, PE (polyethylene) in yellow and PS (polystyrene) in purple.

‘That‘s how we see the world at EVK,’ explains Dr Matthias Kerschhaggl, one of the pioneers in the research and development of this technology, with a smile on his face. ‘In this case we made the invisible chemistry of the material visible. The optimised use of algorithms and the associated machine learning mean that decisions for the further processing of different materials are made in real time. In this way, the product flow in a facility can be continuously monitored with the necessary precision and even small variations are detected. ‘We are very proud of what we have achieved in the last 10 years in terms of food safety and sustainable systems for a more sustainable treatment of the environment and to the benefit of our children,’ explains the father of two.

Even Nature profits from Recycling

An example from the recycling industry shows that the environment also benefits from these new, connected sensor technologies. The well-planned and controlled processing of waste in incineration facilities offers the possibility to generate energy efficiently from existing secondary raw materials and also the chance to protect the environment and to reduce the CO2 emitted by burning fossil fuels excessively.

The Italian recycling industry is working hard to find a solution for local waste management in cities such as Rome and Naples. Incinerators in northern Italy, which comply with EU directives, have been forced to accept waste generated in the rest of the country. It is a fact that plastic and products made from this waste accounted for 2.1%¹ of the Italian GDP¹ as one of Italy’s exports in 2018. In addition to national challenges, the waste issue also poses international hurdles that need to be overcome. Since China, with its ‘National Sword Policy’, seriously intervened in Europe’s recycling structures by only allowing the import of segregated plastic, the sorting of plastic in Italy has also become a relevant factor. This applies, for example, to the export of materials made of different polymers. In addition, the circular economy package stipulates mandatory recycling quotas, i.e. the reuse of waste, for example, as secondary raw materials, for EU member states in future.

The recycling rate for plastic packaging is expected to rise to 55% by 2025. This also means that politicians will have to do their part to help close the loop. ‘It should be borne in mind that recycling a PET bottle is relatively easy, but supermarket sausage packaging is made up of different types of plastic, making it much more difficult to recycle and unsuitable for conventional recycling³,’ says one of the most renowned specialists in waste-processing technology and waste-management research Prof. Roland Pomberger from the University of Leoben, Austria. Technologies such as modern image processing and hyperspectral imaging in particular, which makes it possible for the human eye to see chemical structures, can help. Even though Italy has already achieved the recycling targets for packaging in many areas, it lags behind when it comes to recycling plastics by 41%. This is another area in which integrated, state-of-the-art data-based analysis systems such as hyperspectral imaging can make an important contribution to keeping our environment cleaner and reducing marine pollution with non-reusable plastics.

Sources:

¹ https://wko.at/statistik/laenderprofile/lp-italien.pdf, 20. August 2019

² http://www.worldstopexports.com/top-european-export-countries/, 28. August 2019

³ Interview mit Prof. Pomberger entnommen aus dem Wirtschaftsmagazin Spirit of Styria, Ausgabe Juli 2019